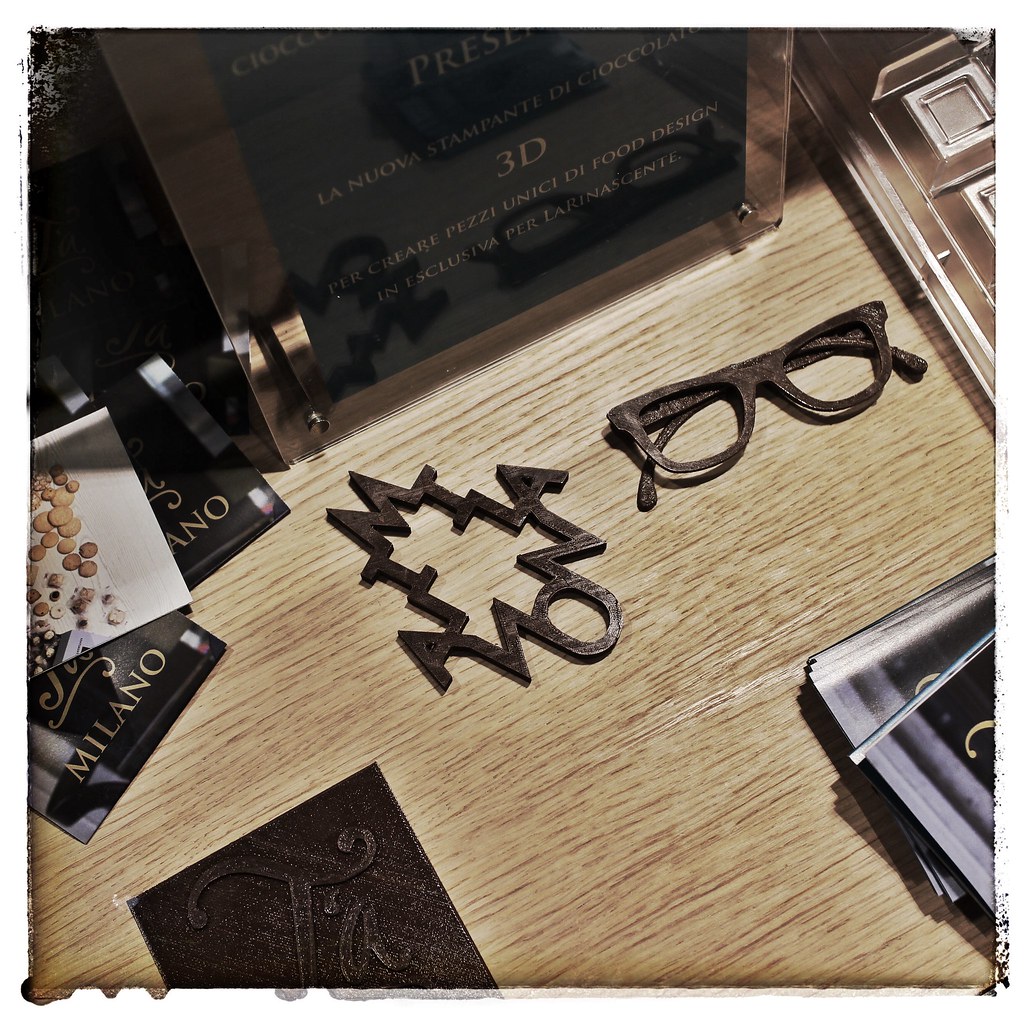

The advent of 3D printing technology has brought about remarkable transformations across multiple industries, including healthcare, aerospace, and manufacturing. This technology, which involves layer-by-layer creation of three-dimensional objects from digital models, has found a particularly intriguing application in the realm of gastronomy, more specifically in the creation of chocolate products. Chocolate 3D printing is essentially a marriage of the artistry involved in traditional chocolate making, with the precision, versatility and complexity offered by additive manufacturing. It presents a whole new world of possibilities, paving the way for the creation of unique and intricate chocolate designs that were previously unattainable through conventional methods.

Chocolate 3D printing is a testament to innovation in the food industry, and it has sparked the interest of major companies and enthusiasts alike.A noteworthy collaboration in the field of chocolate 3D printing is the partnership between The Hershey Company and 3D Systems, resulting in the innovative creation of the CocoJet. This collaboration stands as a proud testament to the potential impact of chocolate 3D printing technology on the chocolate industry and underlines the keen interest of key industry players in this groundbreaking technology.

The CocoJet is a 3D printer that has been specifically designed to 3D print chocolate. It presents users with the ability to create intricate and personalized designs of chocolate by precisely depositing successive layers of the chocolate material based on a digital model. This innovative technology enables chocolatiers, pastry chefs, and even hobbyists to push the boundaries of their creativity and craft unique chocolate creations, previously thought impossible to achieve by hand.

In addition to providing an innovative approach to chocolate design, the advent of chocolate 3D printing also signals a significant shift in consumer behavior. As consumers increasingly seek personalized experiences, the ability of chocolate 3D printing to deliver unique, custom-made chocolate products presents a significant market opportunity.

Understanding 3D Printing Technology

To fully comprehend the impact and potential of chocolate 3D printing, it’s essential to possess a fundamental understanding of the principles and processes involved in 3D printing technology. 3D printing, also known as additive manufacturing, is a process that involves the creation of three-dimensional objects by depositing material layer by layer. This additive process is driven by digital models, which guide the printer in creating the desired shape.

There are various types of 3D printers available, each with its unique capabilities and specialties. In the context of chocolate 3D printing, a specific type of printer is used, which is designed to handle chocolate as the printing material.These printers employ a syringe-like structure and an extruder made from stainless steel for the safe and precise extrusion of the chocolate material. The extruder’s movement is controlled by a CoreXY motor, which significantly improves the printer’s performance and accuracy.

3D printing technology has been successfully adopted across a multitude of industries, including food technology, where its ability to create complex geometries and customized designs makes it an attractive option.For example, in the field of medicine, 3D printing has been used to create patient-specific anatomical models for surgical planning and medical education. This has revolutionized the healthcare sector by providing more accurate and personalized care.In the aerospace industry, 3D printing has enabled the production of lightweight and complex structures that are difficult, if not impossible, to manufacture using traditional methods. The versatility and flexibility of 3D printing have made it a game-changer across various industries, and the chocolate industry has not been left behind.

The potential of 3D printing technology has also been recognized in the food industry, where it’s being used to create edible products with complex shapes and structures. For instance, in the confectionery industry, 3D printing allows for the creation of intricate candies and sweets that would be challenging to produce using traditional methods. This not only adds a touch of novelty to these products but also allows for customization based on individual preferences.

Chocolate 3D Printing Process and Design

The process of chocolate 3D printing involves several crucial steps and considerations. One such critical aspect is temperature control. Given the temperature-sensitive nature of chocolate, maintaining the right temperature is essential to prevent undesired effects such as dripping or blockage during the printing process. To this end, vapor compression refrigeration systems are often employed to maintain the desired temperature within the build chamber.

The design of the 3D printer and the structure of its components also play a significant role in the successful implementation of chocolate 3D printing. For instance, the use of a syringe-like structure and an extruder made from stainless steel ensures the safe and precise extrusion of the chocolate material. Moreover, the CoreXY motor, which is responsible for the movement of the extruder, contributes to the overall performance of the printer by enabling more precise and controlled movements.

In addition to the technical aspects of the printer, the design of the chocolate itself is a vital consideration in achieving successful 3D prints. Complex and intricate designs require careful planning to ensure the structural integrity of the chocolate. Support structures may be necessary to ensure the stability of the printed object during the printing process.

For instance, in the creation of customized chocolate sculptures, the design must take into account the balance and weight distribution of the final piece to avoid collapsing or sagging. The design process involves utilizing specialized software to translate the desired shape and dimensions into a digital model that can be printed layer by layer.

The design process for 3D printed chocolates also requires a deep understanding of the material properties of chocolate, as various factors such as temperature, cooling rate, and the chocolate’s composition can affect the final product’s shape, texture, and taste. For instance, temperature control is critical in ensuring the chocolate maintains the right consistency for printing while preventing it from overheating and losing its desired properties.

Material Composition for Successful Chocolate 3D Printing

The quality and composition of the chocolate used for 3D printing directly impact the quality of the final printed product. The rheological properties of the chocolate, which are affected by the quality of the cocoa beans and the processing conditions during chocolate manufacturing, play a critical role in determining the printability of the chocolate ink.

Research has shown that different types of chocolate require careful tuning of print settings to ensure optimal printability. This is because different types of chocolate have varying compositions, which can affect their melting point, viscosity, and other properties essential to the 3D printing process.

In addition to these considerations, recent studies have explored the possibility of altering the composition of chocolate to suit specific needs. For instance, research has been conducted on the formulation of fat-reduced 3D printed chocolate using water-in-oil emulsions. These formulations have shown the potential for incorporating hydrophilic and lipophilic bioactives into chocolate, opening up future possibilities for functional chocolates.

For example, researchers have successfully incorporated probiotics into 3D printed chocolate, opening up possibilities for functional chocolates with added health benefits. By carefully selecting the composition of the chocolate ink, it is possible to create customized chocolate products that meet specific dietary requirements or cater to individuals with certain health conditions.

The composition of chocolate for 3D printing is also being explored with regard to the inclusion of additional flavors or ingredients. For instance, the inclusion of spices, fruit flavors, or even alcoholic beverages in the chocolate composition could offer a new range of flavors and experiences for consumers. By exploring different compositions of chocolate ink, it’s possible to create a wide variety of unique and personalized chocolate products.

Evolution of Chocolate 3D Printing

The development of chocolate 3D printing technology has been an ongoing process, with significant advancements and collaborations shaping its evolution. The partnership between The Hershey Company, 3D Systems, and the Culinary Institute of America demonstrates the strong commitment to innovate and find real-world applications for chocolate 3D printing. Over time, advancements in printer design, temperature control, and material formulation have contributed to the progress of chocolate 3D printing technology.

One significant advancement in the field of chocolate 3D printing is the improvement in printer speed and accuracy. Early chocolate 3D printers were relatively slow and had limitations in terms of the level of detail they could achieve. However, with advancements in technology, modern chocolate 3D printers can create intricate designs with high precision and at a much faster rate.

Additionally, collaborations between chocolatiers and engineers have played a crucial role in advancing chocolate 3D printing. By combining their expertise, these collaborations have led to the development of new techniques and innovative applications for chocolate 3D printing. For example, the collaboration between The Hershey Company and 3D Systems resulted in the CocoJet, a 3D printer designed specifically for chocolate, which has been used to create intricate and personalized chocolate designs.

The evolution of chocolate 3D printing also reflects the changing consumer preferences in the food industry. As consumers increasingly seek personalized and unique experiences, the ability of chocolate 3D printing to cater to these demands presents a significant market opportunity. This trend is expected to continue in the future, driving further advancements and innovations in chocolate 3D printing.

Benefits and Applications of Chocolate 3D Printing

Chocolate 3D printing offers a plethora of benefits and diverse applications. One of the key advantages is the ability to create personalized pieces and complex structures that were previously challenging to achieve through traditional chocolate-making techniques. The customization possibilities open up new avenues for creativity and unique chocolate experiences.

In the high-end food industry, chocolate 3D printing has found applications in crafting intricate and visually stunning chocolate creations. The ability to precisely control the shape and design of chocolate opens up possibilities for creating artistic and customized edible pieces. Leading restaurants and pastry chefs have been leveraging this technology to create unique desserts that not only taste good but also offer a visual treat.

Furthermore, chocolate 3D printing offers the potential for the customization of nutritional properties. By incorporating bioactives or adjusting the composition of the chocolate, it may be possible to create personalized chocolate products tailored to specific dietary needs or preferences.

For instance, in the field of personalized nutrition, chocolate 3D printing can be utilized to create customized chocolate bars with specific nutrient profiles. This technology enables individuals to have control over the ingredients and nutritional content of their chocolate, allowing them to tailor their indulgence to their unique dietary requirements.

The application of chocolate 3D printing also extends to the educational sector. Schools and universities can utilize this technology to provide students with hands-on experience in 3D printing, CAD design, and food technology. This not only enhances their learning experience but also equips them with practical skills for the evolving job market.

Challenges and Limitations of Chocolate 3D Printing

While chocolate 3D printing holds tremendous potential, it also presents challenges and limitations. Working with chocolate can be complex due to its unique composition and rheological properties. Achieving fine detailing and steep angles in chocolate models can be challenging. Additionally, the incorporation of fillings such as nuts or cookies into 3D printed chocolate models is currently limited. These challenges require further research and development to overcome.

One of the key challenges is the viscosity of the chocolate ink. The viscosity affects the flow rate and the ability to create intricate details. Finding the right balance between viscosity and printability is crucial for achieving successful 3D prints.

Another challenge is the stability of the printed chocolate. Chocolate has a tendency to melt or deform at relatively low temperatures, making it challenging to create stable structures. Researchers are exploring ways to improve the stability of 3D printed chocolate, such as incorporating additives or modifying the printing process to optimize cooling and solidification.

Despite these challenges, the potential benefits and opportunities offered by chocolate 3D printing outweigh the limitations. With ongoing research and development, it is expected that these challenges will be addressed, leading to significant improvements in the quality and capabilities of chocolate 3D printing.

Research and Development in Chocolate 3D Printing

Research efforts are focused on improving the capabilities and quality of chocolate 3D printing. One area of exploration is the development of fat-reduced 3D printed chocolate using water-in-oil emulsions. These emulsions offer the potential for incorporating functional ingredients and bioactives into chocolate formulations, expanding the possibilities for customized and healthier chocolate products.

Furthermore, researchers are investigating the use of alternative materials for chocolate 3D printing. For example, white chocolate, which has a lower melting point than dark chocolate, may provide new opportunities for intricate designs and structures. By exploring different materials and formulations, the potential for chocolate 3D printing can be expanded even further.

In addition to the development of new materials and formulations, researchers are also exploring ways to improve the 3D printing process itself. This includes research on optimizing the temperature and cooling rate during printing, the development of more precise and efficient extruders, and the creation of software that can accurately translate complex designs into 3D printable models.

The collective results of these research efforts are expected to significantly enhance the capabilities of chocolate 3D printing, making it a more versatile and efficient tool for creating unique, personalized chocolate products.

Role of 3D Printing in Customized Nutrition

- 3D printing technology, including chocolate 3D printing, has the potential to revolutionize the concept of customized nutrition. By utilizing 3D printing, it becomes possible to tailor the nutritional properties of food, including chocolate, to meet specific dietary requirements or individual preferences. In hospital care, for example, 3D printed food could be used to provide tailored nutritional needs for patients.

- The ability to customize the composition of chocolate opens up possibilities for creating functional chocolates with added vitamins, minerals, or other beneficial ingredients. By incorporating these ingredients into the chocolate ink, it is possible to create personalized chocolate products that cater to specific nutritional needs.

- Furthermore, personalized nutrition is gaining traction as individuals become more conscious of their health and wellness. Chocolate 3D printing can play a role in this trend by allowing individuals to create customized chocolate products that align with their dietary goals and preferences.

- In addition to customization, 3D printing can also contribute to food sustainability. By precisely controlling the amount of material used, 3D printing can reduce food waste. Moreover, by enabling localized production, 3D printing can also reduce the environmental impact associated with food transportation.

Future Prospects and Advancements in Chocolate 3D Printing

The future of chocolate 3D printing holds promising prospects for growth, efficiency improvements, and scalability in the production process. As the technology continues to advance, it is expected that the limitations and challenges currently faced by chocolate 3D printing will be addressed. This will open up new opportunities for the chocolate industry and allow for further exploration of creative and personalized chocolate experiences.

One area of future advancement is the development of multi-material 3D printing for chocolate. This would enable the creation of complex chocolate designs with different colors, textures, and flavors in a single print. By incorporating multiple materials, the possibilities for creativity and customization in chocolate 3D printing can be expanded.

Another area of focus is the improvement of printing speed and efficiency. Advancements in printer technology and material formulations can significantly enhance the production capabilities of chocolate 3D printing. This would enable chocolatiers and pastry chefs to meet the growing demand for customized and unique chocolate creations.

In terms of market prospects, the demand for personalized and customized products is expected to drive the growth of chocolate 3D printing. As consumers become more interested in personalization and unique experiences, the ability of chocolate 3D printing to cater to these demands presents a significant market opportunity.

Conclusion

Chocolate 3D printing represents a remarkable intersection of technology, artistry, and culinary craftsmanship. Through the collaboration of major players in the industry and ongoing research efforts, chocolate 3D printing has evolved from a novel concept to a viable technology with exciting applications. While challenges and limitations remain, the potential for creating personalized, intricate, and nutrition